AI, Digital Twins, and PLM are reshaping manufacturing by creating virtual replicas of systems for real-time monitoring and optimization. This synergy enhances decision-making, streamlines workflows, and accelerates product development, leading to improved efficiency, reduced costs, and faster time-to-market for manufacturers.

We specialize in the sales and deployment of CAD, PLM, IoT, and AR/VR solutions, including PTC Creo, Windchill, Thingworx, and BricsCAD. Our services cover implementation, training, and ongoing technical assistance, ensuring seamless integration and maximizing operational efficiency through connected, data-driven insights.

Modelcam Technologies specializes in delivering customized software solutions, including AI-driven tools, tailored to the unique needs of manufacturing and engineering businesses. From AI chatbots for customer engagement to factory AI applications, we ensure seamless integration to enhance operational efficiency and business growth.

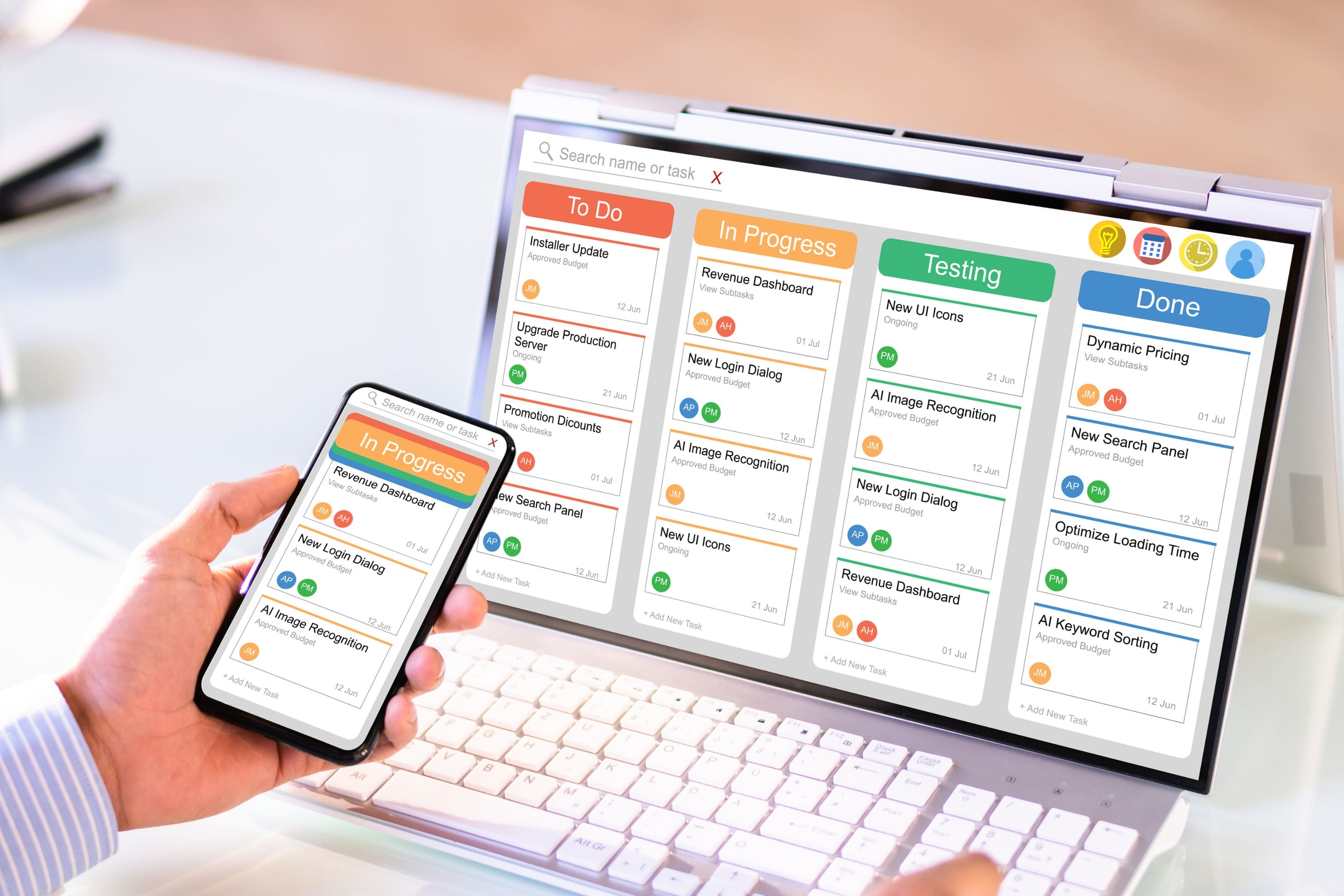

Our software delivery services include end-to-end PLM implementation to streamline product development and the integration of AI technologies into manufacturing workflows. These solutions enhance operational efficiency, drive innovation, and optimize product lifecycle management, empowering businesses to stay competitive in a fast-evolving market.

Our software design services focus on customizing existing CAD solutions to align with your business processes and project requirements. We enhance engineering designs through tailored simulations and modeling, ensuring optimal functionality, improved efficiency, and seamless integration for every project.

AI is revolutionizing manufacturing by automating tasks, optimizing processes, and enabling predictive maintenance. AI in Manufacturing enhances predictive maintenance, quality control, and supply chain management by analyzing real-time data. This technology is driving innovation, increasing efficiency, and enhancing overall manufacturing operations.

Get DetailsA digital twin creates a virtual representation of a physical entity, simulating real-time performance through continuous data integration. It enables monitoring, analysis, and optimization by providing insights into performance, predictive maintenance, and risk management. This technology improves efficiency, and drives innovation in various industries like manufacturing, healthcare, etc.

Get Details

Creo 11, the latest version of PTC’s powerful CAD software, introduces a range of enhancements aimed at improving productivity, simulation, and manufacturing processes. With advanced 3D modeling, simulation tools for heat transfer and structural analysis, and optimized capabilities for composite design, Creo 11 empowers engineers to tackle complex designs with greater efficiency.

New features like cloud integration, AI-powered decision-making, and improved collaboration further streamline workflows, positioning Creo 11 as a leading tool for modern product design and innovation.

Explore the game-changing features of Windchill+, PTC's cutting-edge SaaS PLM solution, empowering manufacturers with speed, agility, and security. Learn how Windchill+ seamlessly integrates with legacy systems, offering frictionless scalability and simplified administration. Partner with Modelcam Technologies, your PLM consultant, to unlock the full potential of Windchill+ and drive business transformation. Click to discover more about Windchill PLM product lifecycle management, and cloud-based PLM services!

With over 18+ years of experience as a trusted PTC partner in India, Modelcam has become the preferred choice for over 165 small & medium manufacturing companies seeking Mechanical 3D CAD software, including PTC Creo. As a leading PTC partner, we ensure our clients receive unmatched support from day one of purchasing CAD software. Our expert engineers apply Knowledge Based Design techniques to help optimize your designs and streamline workflows, maximizing the value of your software investment and ensuring your business success with PTC Creo.

©Copyright 2025. All rights reserved by Modelcam Technologies Private Limited PUNE.